3D printen, ook bekend als additive manufacturing (AM), maakt gebruik van gespecialiseerde poeders om driedimensionale onderdelen te construeren in opeenvolgende lagen. Deze gids is een diepgaand naslagwerk over poeders voor 3D printen - met informatie over types, eigenschappen, specificaties, productiemethoden, belangrijkste leveranciers en prijzen, toepassingen in verschillende sectoren, vergelijkingen met alternatieven, veelgestelde vragen en nog veel meer.

Overzicht van Poeders voor 3D afdrukken

3D-printpoeders zijn grondstoffen voor de productie van additieve onderdelen in kunststof, metaal en keramiek. Belangrijkste kenmerken:

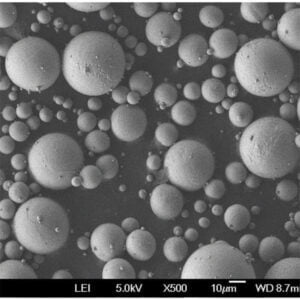

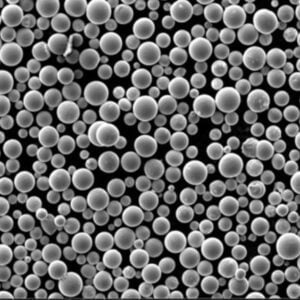

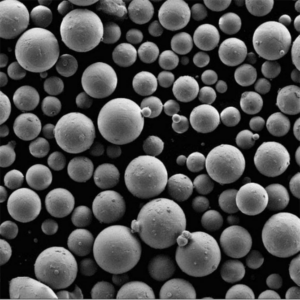

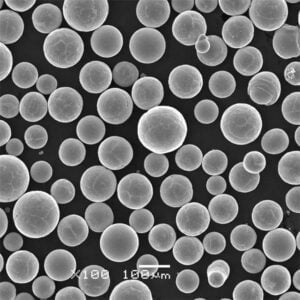

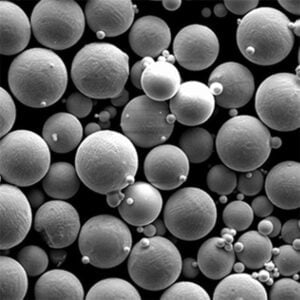

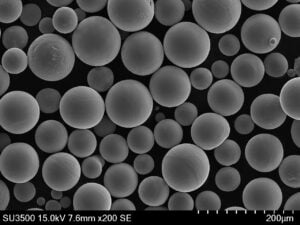

- Staat: Ultrafijne deeltjespoeders

- Groottebereik: Gewoonlijk 10-150 micron

- Morfologie: Meestal bolvormige deeltjesvorm

- Samenstelling: Polymeer, metaallegering, keramiek, zandsteenmengsels

- Belangrijkste eigenschappen: Ontwikkelde deeltjesgrootteverdeling, stroombaarheid, verpakkingsdichtheid en microstructuur

Door de fysische eigenschappen van het poeder en de interacties met thermische/kinetische printprocessen onder controle te houden, maken 3D-printpoeders ingewikkelde onderdeelgeometrieën en gradiënten in materiaalsamenstelling mogelijk die anders niet haalbaar zijn.

Soorten 3D Printing poeders

| Categorie | Materialen | Afdrukmethode |

|---|---|---|

| Kunststoffen | Nylons, ABS, TPU, PEKK, PEEK ... | Selectief lasersinteren (SLS) |

| Metalen | Roestvrij staal, gereedschapsstaal, titanium & legeringen, superlegeringen ... | Direct metaallasersinteren (DMLS) |

| Keramiek | Aluminiumoxide, zirkoniumoxide, siliciumcarbide | Binder jetting, gesmolten afzetting modelleren |

| Composieten | Metaal/kunststofmengsels, zandsteenmengsels | Meerstraalsfusie (MJF), gebonden metaalafzetting |

| Biocompatibel | PEEK, PLGA, TCP... | Selectief lasersmelten (SLM) |

Tafel 1: Belangrijkste categorieën, materialen en bijbehorende printplatforms voor commerciële 3D-printpoeders

Polymeer-, metaal-, keramiek- en composietpoeders ondersteunen de productie van onderdelen voor eindgebruik in de lucht- en ruimtevaart, de auto-industrie, de medische, tandheelkundige en industriële markten.

Productiemethoden

| Methode | Beschrijving | Material Suitability | Voordelen | Nadelen |

|---|---|---|---|---|

| Verneveling | This umbrella term encompasses various techniques that break down molten metal into fine particles. The molten metal is forced through a nozzle into a high-pressure gas or water stream, rapidly solidifying the droplets into spherical particles. | Metals (Iron, Aluminum, Titanium Alloys) | – High production rate – Consistent particle size and shape – Good powder flowability | – Requires high energy input – Potential for oxide formation on particles – Limited to certain materials |

| Gasverstuiving | The most common atomization method, using an inert gas (typically nitrogen) to break up the molten metal. | Similar to Atomization, but generally better surface quality and tighter control over particle size. | – Superior powder quality compared to other atomization methods – Suitable for reactive metals | Similar to Atomization, but higher equipment cost |

| Waterverneveling | Utilizes a high-pressure water jet to fragment the molten metal. More cost-effective than gas atomization but produces less spherical particles. | Some metals (Iron, Copper) and some polymers | – Lower cost than gas atomization – Well-suited for moisture-insensitive materials | – Lower powder quality (irregular shapes) – May not be ideal for high-performance applications |

| Plasma-verneveling | An electric arc heats the feedstock material (metal wire or powder) to a molten state. The molten metal is then ejected through a nozzle and atomized using a plasma torch. | Wide range of materials (metals, alloys, ceramics) | – Can handle high melting point materials – Suitable for creating composite powders | – Complex and high-cost process – Requires stringent safety measures |

| Mechanical Pulverization | A physical process that grinds or mills bulk material into fine powder. | Brittle materials (ceramics, some polymers) | – Simpler and lower-cost setup compared to other methods | – Limited control over particle size and morphology – May introduce impurities during grinding |

| Chemische dampdepositie (CVD) | A chemical process where gaseous precursors react to form a solid deposit on a seed particle. | Metals, ceramics, and some advanced materials | – High purity and precise control over particle composition – Can create complex geometries | – Slow process with limited production rate – High capital investment |

| Electrolytic Atomization | An electrolytic cell is used to decompose a metal anode into ions. The ions then combine with electrons at the cathode to form metal particles. | Metalen | – Environmentally friendly process (avoids high temperatures) – Suitable for moisture-sensitive materials | – Lower production rate than atomization methods – Limited to certain electrolytes and anode materials |

| Sferoïdie | An additional process used to improve the shape of irregularly shaped powders produced by other methods. Involves heat treatment or chemical processes to encourage particle agglomeration into spheres. | Most powder types (metals, polymers, ceramics) | – Enhances powder flowability and packing density – Improves printability | – Adds an extra processing step – May not be necessary for all applications |

Eigenschappen van Poeders voor 3D afdrukken

| Eigendom | Beschrijving | Belang voor 3D printen | Examples & Considerations |

|---|---|---|---|

| Deeltjesgrootte en -verdeling | Refers to the variation in size of individual powder particles and the overall spread across different size ranges. Measured in micrometers (µm). | Plays a crucial role in printability, resolution, and final part density. – Too large: hindered flowability, uneven spreading, and potential for raking defects. – Too small: increased surface area can lead to caking and poor packing, affecting strength. |

– SLS (Selective Laser Sintering): Generally prefers finer powders (20-80 µm) for detailed features. – MJF (Multi Jet Fusion): Slightly larger particles (50-100 µm) can be used due to inkjet technology’s ability to overcome flow limitations. – Metal powders: Tight distribution (narrow range) is ideal for good packing density and minimal porosity in the final part. |

| Deeltjesmorfologie | De vorm van individuele poederdeeltjes. | Impacts how well particles pack together, flowability, and surface finish of the final part. – Spherical: Offer the best packing density and flowability, leading to strong and uniform parts. – Irregular shapes: Can create gaps and inconsistencies, potentially affecting strength and surface quality. | – Plastic powders: Generally spherical or near-spherical for optimal printability. – Metal powders: Can vary depending on the metal and production method. Spherical morphologies are preferred but may be achieved through post-processing techniques like atomization. |

| Vloeibaarheid | The ease with which powder flows under its own weight or with minimal shear force. | Critical for consistent material deposition and even layer formation during printing. – Goede vloeibaarheid: Ensures smooth spreading and minimizes the risk of layer defects. – Poor flowability: Can lead to uneven deposition, inconsistencies, and potential printing issues. | – Powders with a narrow particle size distribution tend to flow better due to less particle size interference. – Additives and surface treatments can be used to improve flowability by reducing friction between particles. |

| Verpakkingsdichtheid | The measure of how tightly powder particles can be packed together. Expressed as a percentage of the total volume occupied by the powder. | Affects the final density, strength, and dimensional accuracy of the printed part. – High packing density: Leads to denser parts with improved mechanical properties and dimensional precision. – Low packing density: Results in parts with higher porosity, potentially weaker and less dimensionally accurate. | – Deeltjesvorm plays a significant role. Spherical particles pack more efficiently than irregular shapes. – Processes like Binder Jetting can benefit from slightly lower packing densities to allow for proper binder infiltration. |

| Sinterbaarheid | The ability of powder particles to fuse or bond together during the 3D printing process, typically through heat or laser energy. | Essential for achieving strong and functional printed parts. – Good sinterability: Enables strong inter-particle bonding, leading to robust and functional parts. – Poor sinterability: May result in weak bonds and potential part failure under stress. | – Material composition: Metals generally have good sinterability due to their inherent ability to form strong bonds at high temperatures. – Polymeerpoeders often require specific additives or post-processing steps (e.g., sintering ovens) to enhance bonding. |

| Chemische samenstelling | The elemental makeup of the powder material. | Determines the final properties of the printed part, such as strength, heat resistance, and biocompatibility. – Material selection is crucial based on the desired application and functional requirements. – Powders can be blended to achieve specific properties (e.g., combining metals for improved strength-to-weight ratio). | – Metaalpoeders can range from pure metals like titanium to complex alloys with tailored properties. – Polymeerpoeders can include nylons, polyamides, and biocompatible materials for medical applications. |

| Thermische eigenschappen | The behavior of the powder material under varying temperatures, including melting point, thermal conductivity, and coefficient of thermal expansion. | Impact factors like dimensional stability, warping, and heat distortion during printing and post-processing. – Controlled heating is essential to avoid exceeding the material’s thermal limits and causing part defects. – Matching thermal properties of powder and build platform minimizes warping and ensures dimensional accuracy. | – Metaalpoeders often have high melting points and require precise temperature control during laser-based processes like SLM (Selective Laser Melting). – Polymeerpoeders may soften or melt at lower temperatures, |

3D-Printpoeder Specificaties

| Eigendom | Beschrijving | Impact on Printability & Part Quality | Materiaal Voorbeelden |

|---|---|---|---|

| Deeltjesgrootte en -verdeling | Refers to the individual particle diameters and the variation within the powder. Measured in microns (µm). | Fine powders (< 50 µm) offer high resolution and surface finish but can be challenging to flow and may require special handling. Coarser powders (> 100 µm) improve flowability but can limit detail and increase surface roughness. A narrow size distribution ensures consistent packing and printing behavior. | Polymeren: Nylon (15-75 µm), Polypropylene (40-100 µm) |

| Deeltjesmorfologie | De vorm van individuele poederdeeltjes. | Spherical particles flow freely and pack efficiently, leading to good printability. Irregular shapes can improve inter-particle bonding but may cause flow issues and require specific printing techniques. | Polymeren: Typically spherical due to manufacturing processes. |

| Apparent Density & Packing Density | Apparent density is the weight of powder per unit volume in its loose, poured state. Packing density is the maximum density achievable after tapping or vibration. | Apparent density affects powder flow and handling. Packing density influences the final density of the printed part and its mechanical properties. Higher packing density generally leads to stronger parts. | Polymeren: Apparent density (0.3-0.8 g/cm³), Packing density (0.5-0.9 g/cm³) |

| Vloeibaarheid | The ease with which powder flows under gravity or with minimal agitation. | Good flowability is crucial for uniform powder spreading during printing. Poor flowability can lead to layer inconsistencies and printing defects. | Polymeren: Typically free-flowing due to their spherical morphology. Additives can be used to improve flowability. |

| Vochtgehalte | The amount of water vapor trapped within the powder particles. | Excess moisture can cause issues during printing, such as steam explosions or inconsistent melting behavior. Most powders require strict moisture control. | Polymeren: Typically very low moisture content (< 0.1 wt%) to prevent hydrolysis and ensure consistent printing behavior. |

| Chemical Composition & Purity | The elemental makeup of the powder and the presence of any impurities. | The chemical composition determines the final properties of the printed part. Impurities can affect printability, mechanical performance, and surface quality. | Polymeren: High purity grade material is used to ensure consistent properties and printability. |

| Thermische eigenschappen | Melting point, glass transition temperature (Tg) for polymers, and thermal conductivity. | Thermal properties influence the printing process parameters and the final microstructure of the printed part. | Polymeren: Melting point and Tg are crucial for setting printing parameters like laser power or bed temperature. |

3D drukpoeder leveranciers

| Materiaal | Belangrijkste toepassingen | Representative Suppliers | Overwegingen |

|---|---|---|---|

| Polymeerpoeder | – Prototyping – Functional parts – Medical devices – Consumer goods | * Polyamide (Nylon): BASF, Evonik, Arkema * Polymelkzuur (PLA): NatureWorks, ExxonMobil Chemical, DuPont * Polypropyleen (PP): Royal DSM, SABIC, Repsol |

* Particle size and distribution impact printability and final part properties. * Material properties like heat resistance, flexibility, and biocompatibility vary. * Consider chemical compatibility with post-processing techniques. |

| Metaalpoeders | – Aerospace components – Automotive parts – Medical implants – Tools and dies | * Titaanlegeringen: AP Powder Company, Höganäs, GE Additive * Roestvrij staal: Carpenter Additive Manufacturing, SLM Solutions, EOS GmbH * Aluminiumlegeringen: Rio Tinto Alcan, DLP Manufacturing, Exone |

* Powder morphology (shape) affects flowability and packing density. * Grain size influences mechanical properties of the final part. * Safety protocols are crucial when handling reactive metal powders. |

| Samengestelde poeders | – Lightweight structures with high strength – Conductive components – Biocompatible implants with enhanced properties | * Polymer-Metal Composites: LPW Technology, Markforged, Desktop Metal * Ceramic-Metal Composites: Sandvik Hyperion, Extrude Hone, Plasma Technik * Polymer-Carbon Fiber Composites: Stratasys, Desktop Metal, Henkel |

* Selection depends on the desired combination of properties (strength, conductivity, biocompatibility). * Interface between different materials requires careful consideration for optimal performance. * Printing parameters may need adjustment compared to single-material powders. |

Toepassingen van Poeders voor 3D afdrukken

Drukpoeders faciliteren op unieke wijze complexe, op maat gemaakte onderdeelgeometrieën in verschillende industrieën:

| Industrie | Voorbeeld Onderdelen | Voordelen |

|---|---|---|

| Lucht- en ruimtevaart | Turbinebladen, raketstraalpijpen, UAV-chassis | Gewichtsvermindering, prestatieverbetering |

| Medisch | Op de patiënt afgestemde implantaten, protheses | Persoonlijke maat, biocompatibiliteit |

| Automobiel | Warmtewisselaars, lichtgewicht chassiselementen | Consolidatie van onderdelen, efficiëntie |

| Industrieel | Aangepaste productiegereedschappen, mallen | Kortere ontwikkelingstijden |

Tabel 5: Belangrijke toepassingssectoren die profiteren van de mogelijkheden van 3D-printpoeder

De mogelijkheid om ontwerpen snel te herhalen en kleine oplages economisch te printen, maakt innovatie van onderdelen voor eindgebruik mogelijk.

Voor- en nadelen van 3D printen op basis van poeder

| Pluspunten | Nadelen |

|---|---|

| High Accuracy and Resolution | Powder Handling and Safety |

| Wide Range of Materials | Beperkte bouwgrootte |

| Minimale ondersteunende structuren | Vereisten voor naverwerking |

| Fast Production Rates | Hoge initiële investering |

Veelgestelde vragen

V: Welke deeltjesgrootte werkt het beste voor metalen 3D printpoeders?

A: 10-45 micron vergemakkelijkt een goede verpakking en spreiding terwijl uitdagingen met ultrafijne poeders rond poederbehandeling vermeden worden. De meeste legeringen presteren goed met een verdeling van 30±15 μm.

V: Welk 3D-printproces voor polymeerpoeder biedt de beste mechanische prestaties?

A: Met selectief lasersinteren (SLS) is een uitstekende fusie en productie van fijne onderdelen mogelijk, waardoor hoogwaardige kunststofonderdelen kunnen worden gemaakt die kunnen wedijveren met spuitgietprocessen of deze zelfs overtreffen.

V: Hoe lang kan ongebruikt 3D-printpoeder worden bewaard?

A: Afgedicht met droogmiddel tegen vocht in een koele, droge omgeving - poeders behouden hun vloei-eigenschappen minstens 12 maanden. Zelfs geopende poeders gaan 6+ maanden mee voordat er merkbare degradatie optreedt.

V: Heeft de kwaliteit van het startpoeder een significante invloed op de eigenschappen van geprinte onderdelen?

A: Ja, de zuiverheid van de poedersamenstelling en een adequate controle van de poedereigenschappen bepalen sterk de mechanische eigenschappen, esthetiek, maatnauwkeurigheid en betrouwbaarheid van het eindproduct.