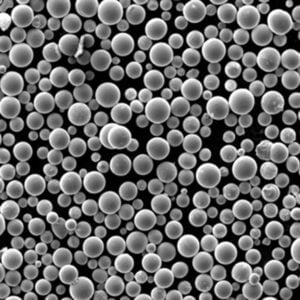

types of metal powders produced by Mechanisch legeren

Mechanical alloying (MA) stands as a powerful tool in the realm of metal powder production, offering incredible versatility in creating a multitude of unique materials. This approach takes a blend of metal powders and subjects them to intense mechanical forces within a high-energy ball mill. Through repeated cycles of cold welding, fracturing, and rewelding, this process fosters the formation of a diverse array of metal powder types:

Single Metal Powders

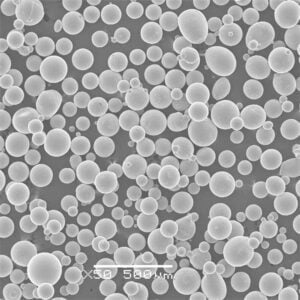

These are the basic building blocks, consisting entirely of a single element, like iron, copper, or aluminum. MA offers a refined approach for producing these powders, often resulting in finer and more homogeneous particle sizes compared to traditional methods.

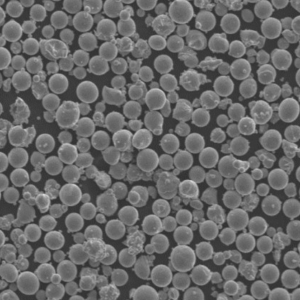

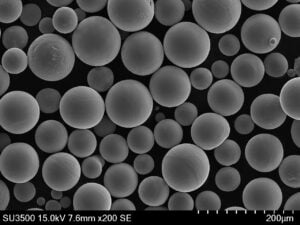

Alloy Powders

Imagine combining two or more elements – mechanical alloying allows you to do just that! This process unlocks the potential to create intricate alloy powders, such as iron-based, nickel-based, or copper-based alloys. These alloys are often sought after for their unique properties, such as enhanced strength, corrosion resistance, or specific electrical characteristics.

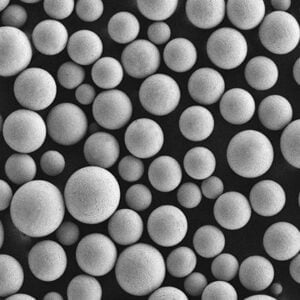

Composite Metal Powders

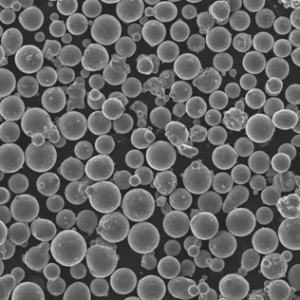

Stepping beyond traditional metallic elements, MA ventures into the realm of composite powders. By incorporating non-metallic elements or compounds, such as ceramics or polymers, it opens doors to innovative materials. These composite powders hold immense potential in applications requiring specific combinations of properties, like wear resistance or lightweight strength.

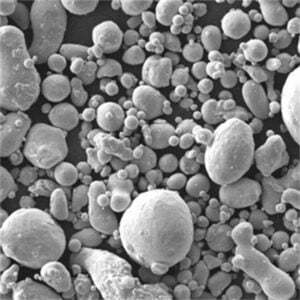

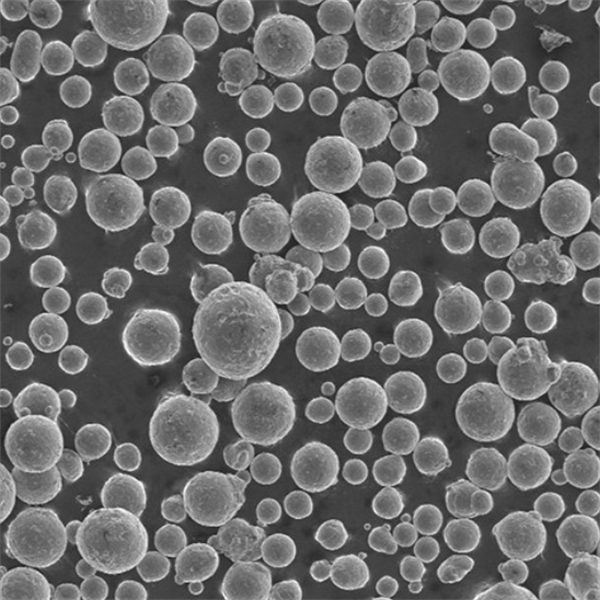

Nano Metal Powders

Delving into the realm of the miniscule, MA has the remarkable capability to create nano metal powders with particle sizes smaller than 100 nanometers. These nanoparticles offer a vast surface area, making them highly desirable for applications in catalysis, sensing, and other fields where precise control on the atomic level is crucial.

Advantages of Mechanically Alloyed Metal Powders

Terwijl mechanisch legeren offers the versatility to produce diverse metal powders, each type boasts specific advantages:

Single Metal Powders

- Enhanced Purity: MA can remove impurities often present in traditional methods, leading to purer and more consistent powders.

- Verbeterde doorstroombaarheid: The refined and uniform particle size enhances flowability, making them easier to handle and process in various applications.

- Eigenschappen op maat: By controlling processing parameters, MA allows for tailoring particle size and morphology, leading to optimized properties for specific needs.

Alloy Powders

- Unieke microstructuur: MA facilitates the creation of finely dispersed and intermixed phases within the alloy, leading to superior strength, hardness, and other desirable properties compared to conventional alloys.

- Non-equilibrium Phases: MA enables the formation of metastable phases, not achievable through conventional melting, unlocking novel material properties with potential applications in high-performance materials.

- Homogeneous Mixing: This process ensures a uniform distribution of elements throughout the powder, leading to consistent and predictable alloy properties in the final product.

Composite Metal Powders

- Synergistic Properties: Combining metallic and non-metallic components allows for tailored properties like high wear resistance (metal-ceramic) or lightweight strength (metal-polymer).

- Multi-Functionality: These powders offer the potential to integrate various functionalities within a single material, simplifying manufacturing processes and reducing component complexity.

- Novel Material Design: The possibilities for combining different elements and compounds open doors to innovative material design, catering to specific application demands.

Nano Metal Powders

- Hoog oppervlak: The extremely small particle size translates to a significantly increased surface area, making them ideal for applications like catalysis, where reactions occur on the surface.

- Unique Properties: Nanosized particles often exhibit unique properties, such as enhanced strength, improved ductility, and superior electrical conductivity, compared to their bulk counterparts.

- Advanced Material Development: These powders pave the way for the development of advanced nanomaterials with tailored properties for applications in electronics, energy storage, and various other cutting-edge fields.

Voordelen van Mechanisch legeren

1. Unmatched Uniformity: Tailoring Composition and Structure with Precision

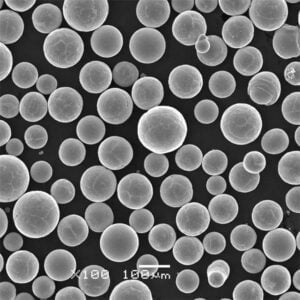

Imagine a painter’s palette where every stroke is perfectly blended, creating a canvas of unparalleled uniformity. This is the essence of MA’s first advantage. It allows for the creation of metal powders with exceptionally uniform composition and refined microstructure. This is achieved through the intense, high-energy collisions that occur during the milling process. These collisions not only physically break down the starting materials but also intimately mix them at the atomic level, leading to a homogeneously distributed mix of elements. Additionally, the high energy input can refine the grain size of the resulting powder, significantly enhancing its strength and other mechanical properties.

2. Beyond the Ordinary: Accessing Unconventional Materials

Traditional methods of creating metal powders often have limitations, especially when dealing with non-equilibrium or metastable phases. These are unique material states that are thermodynamically unstable but can offer exceptional properties. However, MA breaks free from these constraints. Through its high-energy, low-temperature processing, it bypasses the limitations of conventional methods, allowing the creation of these unconventional material phases. This opens doors to entirely new materials with unprecedented properties, potentially leading to breakthroughs in various fields.

3. Embracing the Smallest: Unveiling the Potential of Nano Powders

Imagine a world where materials are built with building blocks so small, they possess entirely new properties. This world becomes a reality with MA’s ability to produce nano metal powders. These powders, with grain sizes less than 100 nanometers, offer a multitude of advantages. Their enormous surface area translates to increased reactivity and enhanced catalytic properties. Additionally, their unique size-dependent properties can lead to improved strength, hardness, and even electrical conductivity. This opens up exciting possibilities in fields such as nanotechnology, catalysis, and the development of advanced materials.

application of mechanical alloying for preparing metal powder

Poeder-Metallurgie: This process utilizes MA powders to create complex and high-performance components. The uniform distribution of elements and fine microstructure of MA powders lead to stronger and more consistent parts compared to traditional methods.

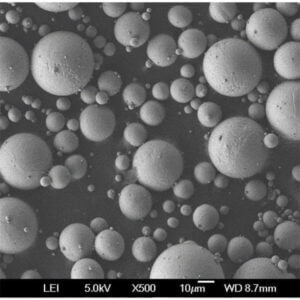

Additieve productie: The intricate nature of MA powders makes them ideal for 3D printing. Their good flowability and precise particle size allow for accurate deposition and intricate part creation.

Katalyse: The high surface area of nano metal powders produced by MA makes them excellent catalysts. They can accelerate chemical reactions in various industrial processes, such as petroleum refining and emission control.

Functional Materials: The unique properties of MA powders, like their tailorable composition and non-equilibrium phases, pave the way for the development of advanced functional materials. These materials can possess specific characteristics like high conductivity, wear resistance, or magnetic properties, making them suitable for applications in electronics, aerospace, and energy sectors.

Specific Application Cases of Mechanically Alloyed Metal Powders:

1. Nano Iron Powder for High-Performance Magnetic Materials:

- Nano iron powders produced by mechanisch legeren (MA) have ultra-fine grain sizes and uniform magnetic domain walls. Compared to traditional iron powders, they exhibit higher magnetic saturation intensity, coercivity, energy product, and permeability.

- These nano iron powders can be applied to prepare high-performance magnetic materials, such as:

- High-performance magnetic recording media: used in hard drives, magnetic tapes, and other storage devices.

- Magnetic sensors: used in automotive, aerospace, medical, and other fields.

- Magnetocaloric materials: used for refrigeration and thermal management.

2. Nano Aluminum Powder for High-Energy Fuel:

- MA-produced nano aluminum powders have a high surface area and high reactivity, leading to faster combustion and more concentrated energy release.

- These nano aluminum powders can be applied to prepare high-energy fuels, such as:

- Rocket propellants: improve thrust efficiency and payload.

- Explosives: used for military and civilian blasting.

- Thermite: used for combustion and welding.

3. Oxide-Metal Composite Powders for Wear-Resistant Materials:

- Oxide-metal composite powders prepared by MA combine the hardness and wear resistance of oxides with the toughness and strength of metals, resulting in excellent wear resistance.

- These composite powders can be applied to prepare wear-resistant materials, such as:

- Cutting tools: improve tool life and processing efficiency.

- Mining machinery parts: extend equipment service life.

- Bearings and seals: improve wear resistance and corrosion resistance.