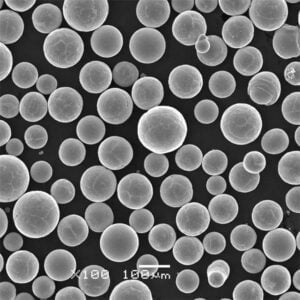

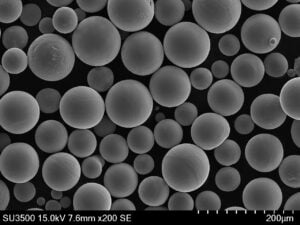

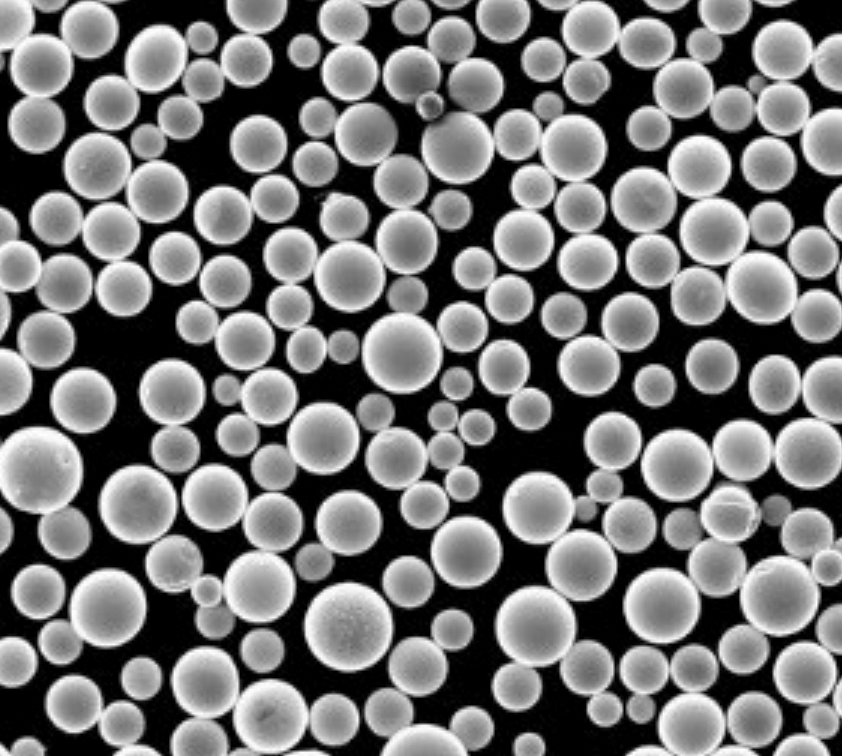

Bolvormig aluminium poeder is een speciaal aluminiumpoeder met deeltjes die bolvormig zijn. Dit poeder heeft verschillende gunstige eigenschappen en toepassingen in vergelijking met standaard aluminiumpoeders.

Overzicht van bolvormig aluminiumpoeder

Sferisch aluminiumpoeder heeft een superieure vloeibaarheid, verpakkingsdichtheid en andere kenmerken die het geschikt maken voor verschillende industriële toepassingen. Enkele belangrijke details:

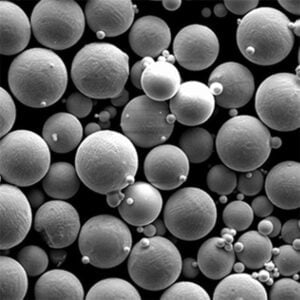

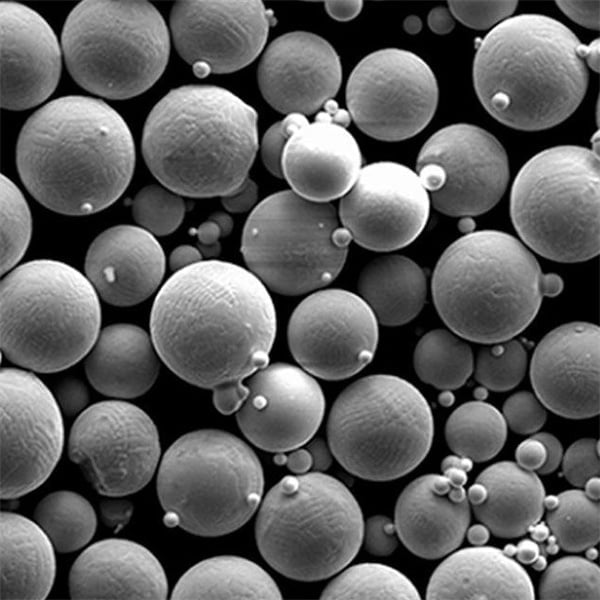

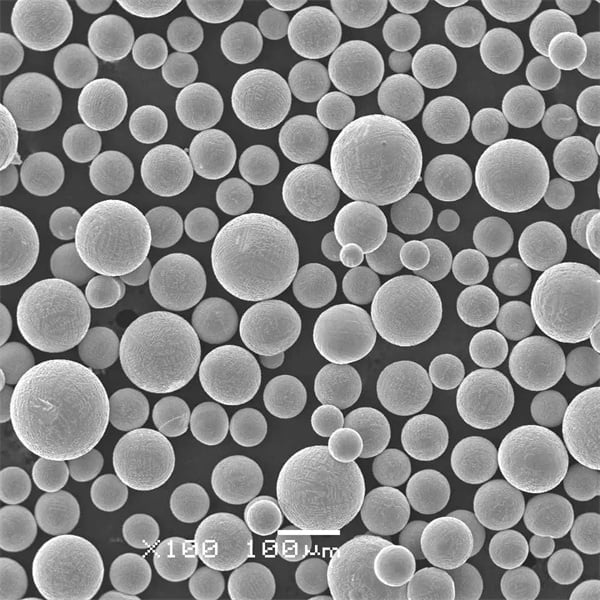

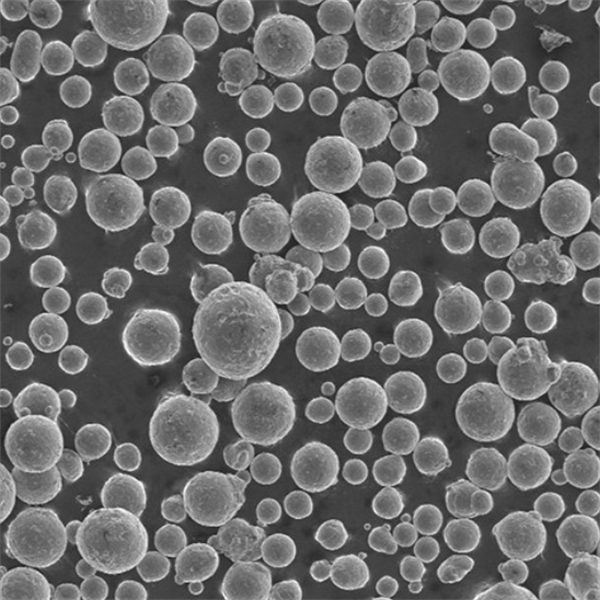

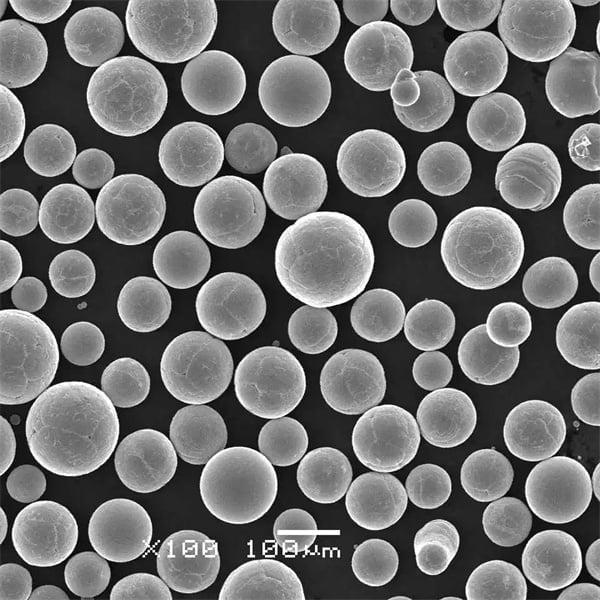

- Bestaat uit kleine aluminiumdeeltjes in een bolvorm in plaats van onregelmatige vlokken

- De deeltjesgrootte varieert gewoonlijk van 1 μm tot 150 μm

- Geproduceerd door atomisatieproces van gesmolten aluminium

- Eigenschappen kunnen worden aangepast op basis van verstuivingsparameters

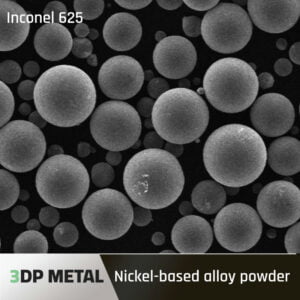

- Gebruikt in explosieven, pyrotechniek, lassen, metaal 3D printen en meer

Voordelen: Uitstekende stroombaarheid, hogere bulkdichtheid, lager oppervlak, uniforme deeltjesgrootteverdeling, lage porositeit, lager oxidegehalte, gecontroleerde chemie.

Nadelen: duurder dan standaard aluminiumpoeders.

Soorten bolvormig aluminiumpoeder

Er zijn een paar belangrijke soorten bolvormig aluminiumpoeder, gecategoriseerd op productiemethode en eigenschappen:

| Type | Beschrijving |

| Verstoven | Gemaakt door verneveling met inert gas of water; meest voorkomende type met strakke verdeling. Gebruikt voor vermindering van explosieve gevoeligheid, verbeterde kruitstroom en verpakking. |

| Sferoïdaal | Onregelmatig aluminiumpoeder omgezet in bolletjes met behulp van processen zoals heet isostatisch persen. Lagere kosten maar bredere distributie. |

| Plasma Verstoven | Geproduceerd met plasma in plaats van gas/water. Zeer klein, uniform poeder tot 1 μm voor geavanceerde toepassingen. |

| Aluminium schot | Lage porositeit en precieze diameters. Gebruikt voor stralen/oppervlakteprofilering. Meestal groter dan poeders. |

Deze verschillende soorten bolvormig aluminiumpoeder hebben specifieke samenstellingen, afmetingen, productiemethoden en toepassingen waarvoor ze het meest geschikt zijn.

Samenstelling van bolvormig aluminiumpoeder

Bolvormig aluminiumpoeder kan bestaan uit puur aluminium of verschillende aluminiumlegeringen die zijn aangepast om bepaalde eigenschappen te verkrijgen. Enkele voorbeelden:

| Type | Legerende elementen | Kenmerken |

| Zuiver Al | – | Zacht, lagere sterkte; gemakkelijk gevormd en gelast. |

| 6061 | Mg, Si | Middelmatig sterk; matig corrosiebestendig. |

| 7075 | Zn, Mg, Cu | Hoge sterkte; vaak gebruikt voor ruimtevaarttoepassingen. |

Specifieke onzuiverheidslimieten in de chemie en strakke deeltjesverdelingen worden aangehouden voor betrouwbare prestaties. Aangepaste legeringen zijn mogelijk voor gespecialiseerde mechanische, thermische of chemische eigenschappen.

Eigenschappen van bolvormig aluminiumpoeder

| Eigendom | Beschrijving | Benefit in Additive Manufacturing & Other Applications |

|---|---|---|

| High Flowability | Spherical aluminum powder particles move freely with minimal friction due to their smooth, rounded shape. This allows for even distribution within a hopper or feeder system, critical for consistent material deposition in Additive Manufacturing (AM) processes like Selective Laser Melting (SLM) or Electron Beam Melting (EBM). In traditional techniques like pyrotechnics or metal injection molding (MIM), good flowability ensures uniform packing during mold filling, leading to predictable product quality. | * Consistent Layer Formation in AM: Even powder flow enables precise material placement during each layer in AM, resulting in accurate part geometries and minimized defects. * Verminderde segregatie: Spherical particles are less prone to segregation, where larger or denser particles settle out during transport. This maintains a homogeneous powder mixture for consistent material properties throughout the build. * Verbeterde efficiëntie: High flowability allows for faster powder dispensing and minimizes waste, leading to efficient production processes. |

| High Packing Density | Spherical particles pack together more efficiently than irregularly shaped powders. This translates to a higher density of aluminum particles per unit volume, maximizing material utilization in AM and achieving a denser final product. | * Stronger Parts in AM: Higher packing density in the powder bed allows for a greater amount of aluminum to be melted during AM, leading to parts with enhanced mechanical strength and improved load-bearing capabilities. * Verminderde porositeit: Dense packing minimizes voids or air gaps within the powder bed, resulting in a more compact final product with less porosity. This translates to better structural integrity, corrosion resistance, and overall performance. * Materiaaloptimalisatie: High packing density allows manufacturers to use less powder to achieve the desired final part density, leading to material cost savings. |

| Uniform Particle Size Distribution | Spherical aluminum powder is typically produced with a narrow range of particle sizes. This consistency ensures predictable material behavior during processing. | * Improved Process Control: Consistent particle size allows for optimized laser or electron beam parameters in AM, leading to more uniform melting and better control over the final microstructure of the part. * Beperkt oppervlak: A narrower particle size distribution minimizes the overall surface area of the powder, leading to potentially lower oxidation rates during storage and improved flow characteristics. * Minimized Segregation: Similar-sized particles are less prone to segregation within the powder bed, ensuring consistent material properties throughout the build. |

| Low Surface Area | Compared to irregular powders with a high surface area, spherical aluminum powder has a smaller total surface area per unit volume. This characteristic offers advantages in various applications. | * Reduced Oxidation: A lower surface area minimizes the exposure of aluminum particles to oxygen, leading to less oxidation during storage and handling. This helps maintain powder quality and material properties. * Verbeterde doorstroombaarheid: Lower surface area contributes to smoother interactions between particles, enhancing flowability and enabling efficient powder handling. * Verbeterde thermische geleidbaarheid: The spherical shape minimizes internal resistance to heat flow, potentially leading to improved thermal conductivity in the final product. |

| Tailored Properties | Spherical aluminum powder can be produced with various alloying elements to achieve specific properties for different applications. | * Breed scala aan toepassingen: By incorporating specific elements like silicon (Si), magnesium (Mg), or copper (Cu), manufacturers can tailor the powder’s properties like strength, ductility, or electrical conductivity to suit diverse AM and industrial needs. * Functionele onderdelen: Alloyed spherical aluminum powder allows for the creation of functional parts in AM with properties exceeding those of pure aluminum, opening doors for advanced applications. * Lightweight Performance: Aluminum alloys maintain the inherent lightness of aluminum while offering enhanced mechanical properties, making them ideal for weight-critical applications in aerospace, automotive, and other industries. |

Kenmerken van bolvormig aluminiumpoeder

Om optimaal te functioneren in toepassingen, sferische aluminiumpoeders hebben strenge normen voor kenmerken zoals:

| Kenmerkend | Typisch bereik |

| Deeltjesvorm | Bolvormig; Minimale satellieten |

| Deeltjesgrootte | 1 – 150 μm |

| Grootteverdeling | D10: D50-verhouding > 0,7 |

| Oxide-gehalte | < 3,0% in gewicht |

| Schijnbare dichtheid | 0,85 - 2,0 g/cm3 |

| Tik op dichtheid | > 75% dichtheid |

| Hausner verhouding | 1,25 maximaal |

| Stroomsnelheid | 25-35 sec, 50g monster |

Door deze consistentie te handhaven zijn betrouwbare en herhaalbare prestaties mogelijk. Specificaties kunnen worden aangepast op basis van de vereisten van de toepassing.

Toepassingen van sferisch aluminiumpoeder

| Sollicitatie | Beschrijving | Advantages of Spherical Aluminum Powder | Industrie |

|---|---|---|---|

| Additieve Productie (3D printen) | Spherical aluminum powder is a key material in 3D printing processes like Selective Laser Melting (SLM) and Powder Bed Fusion. These techniques use lasers to selectively melt layers of powder, building complex, near-net shape components. | * Vloeibaarheid: Spherical particles flow freely, enabling smooth and consistent deposition during the printing process. * Verpakkingsdichtheid: Spherical shapes pack tightly, minimizing voids and creating strong, dense final parts. * Laserabsorptie: The smooth surface of spheres reflects less laser energy, leading to more efficient melting and improved material properties. * Afwerking oppervlak: Spherical aluminum powder results in smoother surface finishes on printed parts, reducing the need for post-processing. |

Aerospace, Automotive, Medical, Dental |

| Metaalspuitgieten (MIM) | MIM is a manufacturing technique that combines metal powder with a binder to create a feedstock that can be injection molded. The binder is then removed through a debinding process, leaving a near-finished metal part. Spherical aluminum powder is well-suited for MIM due to its: * Vloeibaarheid: Similar to 3D printing, good flowability is crucial for even distribution in the mold cavity. * Verpakkingsdichtheid: High packing density leads to parts with minimal shrinkage and good dimensional accuracy. * Sinterbaarheid: Spherical particles promote better sintering (bonding) during the debinding process, resulting in stronger parts. |

* Complexe geometrieën: MIM allows for the production of intricate metal parts with high precision. * Massaproductie: MIM is suitable for high-volume production of consistent parts. * Material Variety: Spherical aluminum powder can be combined with various alloying elements to achieve specific properties. |

Consumer Electronics, Automotive, Medical Devices, Firearms |

| Thermisch spuiten | Thermal spraying involves melting metal powder and propelling it at high velocity towards a substrate. The molten particles impact and adhere to the surface, creating a coating that can improve properties like wear resistance, corrosion resistance, and thermal conductivity. Spherical aluminum powder offers advantages in thermal spraying, including: * Splat Morphology: Spherical particles flatten into splats with a larger contact area, enhancing adhesion to the substrate. * Reduced Rebound: Due to their shape, spherical particles experience less rebound compared to irregular shapes, leading to higher deposition efficiency. * Controllable Coating Properties: Particle size and distribution can be precisely controlled to achieve desired coating characteristics. |

* Refurbishment: Thermal spraying can restore worn or damaged components, extending their service life. * Functional Coatings: Aluminum coatings can improve heat dissipation, electrical conductivity, and reflectivity. * Lichtgewicht: Aluminum offers a lightweight alternative to heavier materials used in thermal spraying. |

Aerospace, Automotive, Power Generation, Oil & Gas |

| Pyrotechniek | Spherical aluminum powder is a fuel source in some pyrotechnic compositions. Its advantages include: * High Burning Rate: The spherical shape promotes efficient and uniform burning, leading to brighter and more predictable pyrotechnic effects. * Controllable Particle Size: Particle size can be tailored to influence the burning rate and color effects in the pyrotechnic display. * Veiligheid: Spherical aluminum powder can be safer to handle compared to irregularly shaped aluminum powders due to reduced dust generation. |

Fireworks Manufacturing |

Specificaties van bolvormig aluminiumpoeder

Sferisch aluminiumpoeder is verkrijgbaar onder verschillende standaardbenamingen en specificaties per industrie, procesvereisten en uiteindelijke toepassingen:

| Standaard | Cijfers | Deeltjesgrootte | Veel voorkomende toepassingen |

| ASTM B801 | Verstoven aluminium; Grade A | 10-150 µm | Thermische spuitcoatings; drukdraden |

| AMS 4376 | Klasse 1A; Klasse 3 | 10-53 μm; 38-106 μm | Vaste raket drijfgassen; explosieven |

| AMS 4377 | Klas 1-3 | 5-15 μm | Pyrotechniek; ontstekingsmengsels |

| Alcan MD-202 | MD-202SD; MD-202HD | 20-180 μm | Thermische spuitpoeders |

Labels geven duidelijk de relevante kwaliteit, maatserie, lotnummer, productiedatum en andere details aan.

bolvormig aluminium poeder leveranciers

Enkele toonaangevende wereldwijde leveranciers van bolvormig aluminiumpoeder zijn:

| Bedrijf | Plaats |

| Atlantische apparatuuringenieurs | Bergen, NJ; VS |

| Luxfer Magtech | Manchester; UK |

| Nippon Verstoven Metaalpoeders Corp | Japan |

| Hoganas | Zweden |

| Metaalpoeders maken | Groot-Brittannië |

De logistiek van de toeleveringsketen, de minimale bestelhoeveelheid (MOQ) en de prijs variëren tussen leveranciers op basis van geografische regio, productiecapaciteit, aanpassingsopties en andere factoren.

sferisch aluminium poeder Pricing

| Factor | Beschrijving | Impact op de prijs | Voorbeeld |

|---|---|---|---|

| Puurheid | The percentage of aluminum metal present in the powder. Higher purity grades are more expensive. | Directly proportional | – 99.5% pure spherical aluminum powder: Lower cost. – 99.9+% pure spherical aluminum powder: Higher cost. |

| Deeltjesgrootte | The diameter of the individual spherical particles. Finer powders are generally more expensive. | Directly proportional | – 10-45 microns: More affordable, commonly used in pyrotechnics and metal injection molding. – 1-3 microns: More expensive, used in 3D printing and high-performance coatings. |

| Oppervlakte | Relates to particle size. Finer powders have a larger total surface area, potentially increasing cost due to processing requirements. | Directly proportional | – Larger surface area powders may require additional treatment to prevent agglomeration (clumping), impacting price. |

| Bolvormigheid | How perfectly spherical the particles are. A more spherical shape is generally more desirable and expensive. | Directly proportional | – Highly spherical particles flow more easily, pack more densely, and offer superior performance in some applications, leading to a higher price. |

| Hoeveelheid | The amount of spherical aluminum powder purchased. Bulk purchases typically offer a lower price per unit weight. | Indirectly proportional | – Smaller quantities (grams or kilograms) are typically more expensive per unit weight than larger quantities (tonnes). |

| Fabrikant | The reputation and production methods of the supplier can influence price. | Varieert | – Reputable manufacturers with high-quality control processes may charge more than lesser-known suppliers. – Manufacturers using specialized atomization techniques to achieve specific particle size or sphericity may have a price premium. |

| Demand & Availability | Market forces of supply and demand can affect price. | Varieert | – Periods of high demand or limited supply can drive prices up. – Conversely, excess supply may lead to lower prices. |

Voor- en nadelen van bolvormig aluminiumpoeder

| Functie | Pluspunten | Nadelen |

|---|---|---|

| Vloeibaarheid | Spherical aluminum powder excels in flowability due to its smooth, round particles. This allows for easier and more consistent movement within processing equipment, reducing issues like segregation and jamming. Improved flowability translates to faster production times, better packing in molds, and ultimately, more uniform finished products. | While superior to irregular powders, spherical aluminum powder may still exhibit some limitations in flowability, particularly for very fine particle sizes. Additionally, factors like moisture content and surface oxidation can slightly hinder flow characteristics. |

| Verpakkingsdichtheid | The spherical shape of the powder particles enables them to pack together more tightly, resulting in higher packing density compared to irregular powders. This translates to a greater amount of aluminum powder being packed into a specific volume, leading to components with higher density and improved mechanical properties. | Spherical aluminum powder may have a slightly lower apparent density compared to irregular shapes due to the presence of air gaps between the spheres. However, this is often outweighed by the benefits of higher packing efficiency. |

| Uniform Melting & Densification | The consistent size and shape of spherical aluminum powder contribute to more uniform melting behavior during sintering or additive manufacturing processes. This allows for better control over the final microstructure of the component, minimizing internal defects and promoting a more even distribution of porosity. | While offering advantages, spherical aluminum powder might require slightly adjusted processing parameters compared to irregular powders to achieve optimal results. This highlights the importance of tailoring the manufacturing process to the specific powder characteristics. |

| Porosity & Mechanical Properties | The improved packing density and uniform melting behavior of spherical aluminum powder lead to reduced porosity within the final product. This translates to improved mechanical properties like tensile strength, fatigue resistance, and ductility. Components with less porosity are generally stronger, more durable, and less prone to cracking or failure. | The presence of even minimal residual porosity, though significantly reduced compared to irregular powders, can still have an impact on the overall mechanical properties. Careful selection of processing parameters and potential post-processing techniques can further minimize porosity. |

| Oppervlakteafwerking | Due to the smooth, spherical nature of the powder particles, components fabricated using spherical aluminum powder often exhibit a superior surface finish. This reduces the need for extensive post-processing steps like grinding or polishing, leading to improved aesthetics and potentially enhanced functional performance in tribological applications. | The surface finish achievable with spherical aluminum powder can be influenced by factors like particle size distribution and the chosen manufacturing process. However, compared to irregular powders, a smoother surface finish is generally a notable advantage. |

| Production Cost | Spherical aluminum powder production methods like gas or water atomization tend to be more complex and energy-intensive compared to simpler techniques used for irregular powders. This translates to a higher cost for the spherical powder itself. | The increased cost of spherical aluminum powder needs to be weighed against the benefits it offers in terms of improved product quality, processing efficiency, and potentially reduced waste due to lower rejection rates. |

| Deeltjesgroottebereik | While spherical aluminum powder is available in a wide range of particle sizes, there may be limitations compared to irregular powders. Producing very fine spherical particles can be more challenging and expensive. | The selection of the optimal particle size for a specific application is crucial. While a wider range with finer options might be desirable, the available options for spherical aluminum powder are still quite comprehensive for most applications. |

Veelgestelde vragen

V: Wat is het verschil tussen bolvormig en geatomiseerd aluminiumpoeder?

A: Verstoven aluminiumpoeder kan een licht onregelmatige vorm hebben, hoewel de deeltjesgrootteverdeling nog steeds nauwkeurig wordt gecontroleerd. Sferische aluminium poederdeeltjes hebben een precieze bolvorm door gespecialiseerde verstuivingsprocessen.

V: Is bolvormig aluminiumpoeder gevaarlijk?

A: Sommige soorten kunnen pyrofoor zijn, waardoor speciale behandeling in een inerte atmosfeer nodig is. Anders is het over het algemeen veilig, met gezondheidsrisico's vergelijkbaar met andere aluminiumpoeders waarvoor maskers nodig zijn om inademing te voorkomen. Raadpleeg altijd het veiligheidsinformatieblad (MSDS).

V: Wat is de typische bulkdichtheid van bolvormig aluminiumpoeder?

A: Bulkdichtheden variëren tussen 0,4-1,2 g/cm3 afhankelijk van de exacte samenstelling en poederkenmerken. Waarden van meer dan 1 g/cm3 zijn gebruikelijk voor veel bolvormige aluminium poederspecificaties.

V: Hoe kies ik de juiste maat bolvormig aluminium poeder?

A: Houd rekening met factoren zoals: beperkingen van de productiemethode, dichtheidseisen, behoeften aan oppervlakteafwerking, reactiviteit, eigenschappen van het uiteindelijke onderdeel en beschikbare legeringopties. De beste aanbeveling krijg je door de details van de toepassing met de leveranciers te bespreken.

V: Kunnen deze sferische poeders worden gebruikt in voedingsmiddelen/medische toepassingen?

A: Bolvormig aluminium wordt over het algemeen zelf niet gebruikt in voedingsmiddelen of medische toepassingen, hoewel aluminiumlegeringen die voldoen aan strenge normen met betrekking tot onzuiverheden en verwerking op maat kunnen worden gemaakt voor bepaalde scenario's waarvoor niet-toxiciteit vereist is. Speciale nalevingsoverwegingen zouden vereist zijn.

Conclusie

Sferisch aluminiumpoeder biedt superieur stromingsgedrag, dichtheid, reactiviteitscontrole, oppervlakteafwerking en andere eigenschappen in vergelijking met standaard aluminiumpoeders. Aanpassingen via gespecialiseerde verstuivingsprocessen maken het mogelijk om te voldoen aan veeleisende toepassingen in de ruimtevaart, defensie, additive manufacturing en geavanceerde keramische industrieën. Door samen te werken met deskundige leveranciers kunnen de juiste specificaties worden gekozen. Ondanks de hogere kosten bieden de verbeterde consistentie en componentprestaties een uitstekende waarde voor kritieke toepassingen. Voortdurende ontwikkelingen richten zich op verbeterde maatverdelingen, een lager oxidegehalte en betere controle over legeringstoevoegingen.